IML Thermoforming Container Labels

IML thermoforming is an advanced technology in the packaging industry that delivers a high-quality and aesthetically pleasing product by combining simultaneous molding and labeling processes. In this method, heated plastic sheets are formed into the shape of the mold, while labels are placed directly into the mold and fused with the plastic.

Introduction to IML Thermoforming Containers

IML thermoforming is an advanced technology in the packaging industry that delivers a high-quality and aesthetically pleasing product by combining simultaneous molding and labeling processes. In this method, heated plastic sheets are formed into the shape of the mold, while labels are placed directly into the mold and fused with the plastic. This process allows for the production of durable, attractive, and completely sealed packaging.

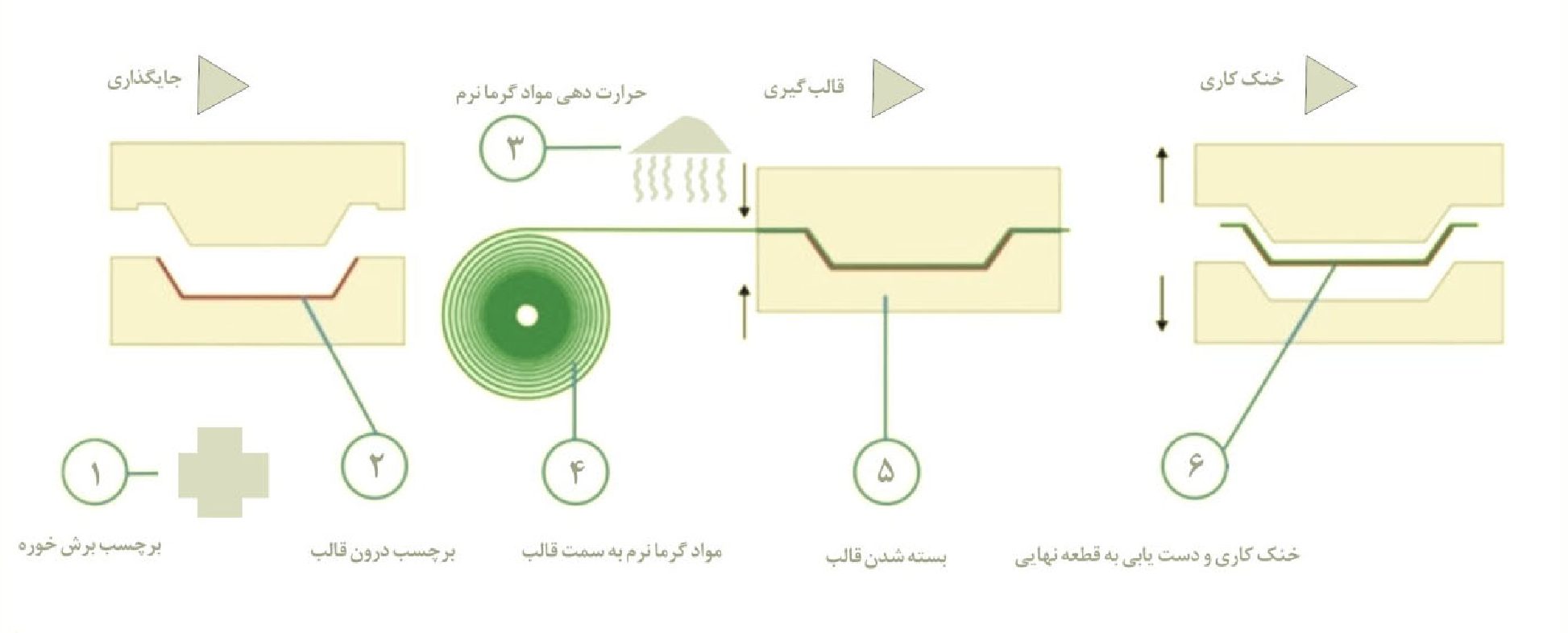

This method is used to produce rigid plastic packaging. The process is based on heating TIML, allowing the TIML to take the shape of the forming tool. When the plastic cools, the forming tool solidifies. Thermoforming is often used to produce liquid packaging. In this method, multi-layer sheets are sealed and become oxygen barrier.

TIML or IML thermoforming means that the product shape is formed during the heating process. The IML label is placed in the mold before forming and fuses with the heated plastic sheet when the final package is formed. Then the plastic cools, the mold opens, and the product is removed with the label.

IML labels have high resistance to heat and cold, and containers with this type of label can be used in the microwave and IML containers can be used over and over again.

Applications of IML Thermoforming

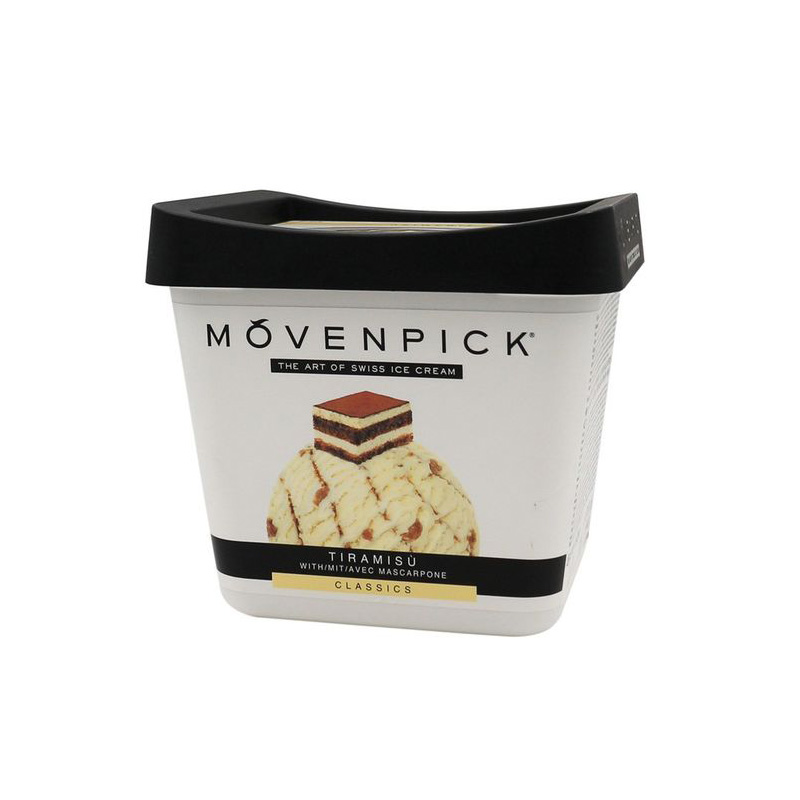

- Food Packaging: IML thermoforming containers are used to produce durable and leak-proof packaging for food products such as yogurt, cheese, ice cream, and other products.

- Pharmaceutical Industries: This technique is used in the packaging of pharmaceutical products that require high protection.

- Household Products: Beautiful and durable plastic containers used in homes, such as paint and oil buckets, are produced using IML thermoforming.

Features of IML Thermoforming

- High Resistance: Containers produced with IML thermoforming have excellent resistance to corrosion, solvents, and harsh environmental conditions.

- Leak-Proof: These products prevent leakage of contents due to their strong structure.

- Beautiful and Attractive Design: IML thermoforming printing technique allows for the production of products with a beautiful appearance and durable labels.

- Heat Resistance: IML thermoforming containers are ready to withstand high and low temperatures and can be used in the microwave.

NEW WORLD Holding; IML Thermoforming Container Manufacturer

NEW WORLD Holding, as one of the experienced manufacturers in the field of IML thermoforming container production, is ready to provide services and produce high-quality products in the shortest possible time. We offer products with the highest standards and competitive prices by utilizing advanced technologies and a specialized team.

Reviews

There are no reviews yet.